customized PCB printed circuit board assembly

China, Shanghai City, Shanghai - view exact locationCategory

Product Information

Order volume from: On request

Delivery terms: Pickup

Description

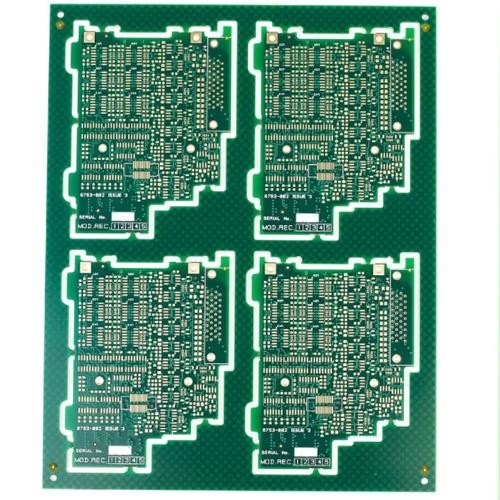

PCB depanelization is a critical process in the electronics industry that facilitates the production of large-scale assemblies. In the manufacturing of printed circuit boards (PCBs) and surface mount technology (SMT), the throughput of production lines can be significantly enhanced by designing PCBs as clusters, consisting of smaller individual boards intended for use in the final product.

These panel or multi-block clusters are subsequently subject to a depanelization process, whereby the large panel is broken down. The timing of this operation varies depending on the specific product requirements. In some cases, depanelization occurs right after the SMT process, while in other instances, it may follow the in-circuit test (ICT), soldering of through-hole components, or even take place just prior to the final assembly of the printed circuit board assembly (PCBA) in the enclosure.

By effectively executing the PCB depanelization process, manufacturers can optimize the production flow, achieve higher productivity, and ensure the proper functioning of the final electronic products.

Business

Business