Ingot measurements on aluminium or steel before scalping

Germany, Berlin Land, Berlin - view exact locationCategory

Product Information

Order volume from: On request

Delivery terms: Pickup

Description

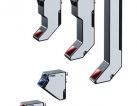

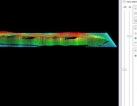

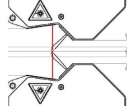

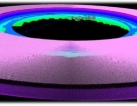

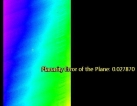

Introducing the innovative solution for assessing rotating parts - the QuellTech Q6 Laser Laser Scanners. With the ever-increasing complexity of rotating parts, it becomes crucial to consider numerous parameters such as concentricity, radial run-out, axial run-out, thickness, diameter, planarity, and surface defects. QuellTech has developed a game-changing solution that tackles these challenges head-on. The Q6 Laser Laser Scanners consist of a configuration of three scanners, each assigned to a specific lateral surface of the rotating part. By precisely orienting the laser lines in opposite directions, the scanners enable accurate determination of thickness. Additionally, the third scanner measures the outer circumference of the wheel, providing valuable insights into the diameter and radial run-out. To ensure precision and reliability, all scanners are equipped with encoder signals supplied by the rotary axis and synchronized triggering. This unique capability enables the precise localization of any potential defects on the wheel. With a resolution of approximately 30 µm, the Q6 Laser Laser Scanners deliver high-quality measurements. Each scan generates a cloud of several million points, providing a comprehensive and detailed analysis of the rotating part. QuellTech's Q6 Laser Laser Scanners revolutionize the assessment of rotating parts, ensuring optimal performance and quality across various industries.

Business

Business