Detection of Surface Defects with Laser Triangulation

Germany, Berlin Land, Berlin - view exact locationCategory

Product Information

Order volume from: On request

Delivery terms: Pickup

Description

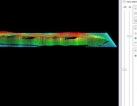

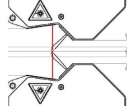

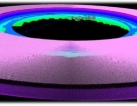

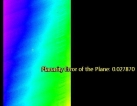

Product Description:Introducing our advanced tactile equipment designed specifically for the metal industry. We understand the particular challenges faced when determining the deepest point on a rough metal surface. Accuracy and precision are crucial, as removing too much material or leaving behind defects can be costly. That's why our equipment is designed to address these challenges head-on.Our equipment features parallel arrangement, ensuring that the complete width of the slabs is covered. The sensors are meticulously calibrated to a common coordinate system and mounted on a movable gantry. Prior to measurement, the slabs are securely fixed in place. The scanners, driven by an electric motor, are guided over the measuring object, providing a comprehensive scan.With the use of our cutting-edge QuellTech image processing software, the point cloud data recorded by the four scanners is consolidated in a PC. This software not only calculates the difference between the highest and lowest points of the corresponding surface but also compensates for any inclination of the slab, ensuring accurate results. Our equipment provides the precise measurements needed to eliminate defects and optimize milling cycles, enhancing efficiency and quality in the metal industry.

Business

Business