Laser Sensor for Seal Surface Inspection

Germany, Berlin Land, Berlin - view exact locationProduct Information

Order volume from: On request

Delivery terms: Pickup

Description

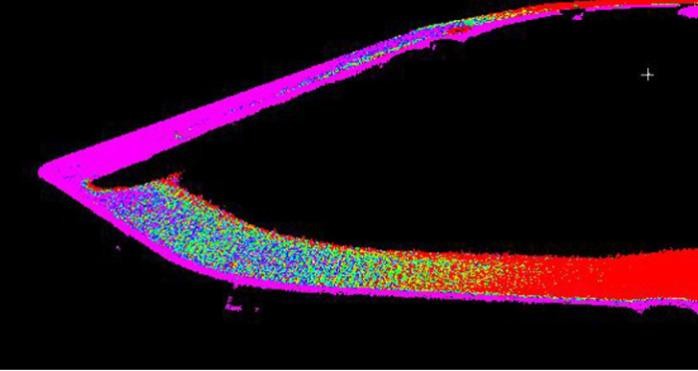

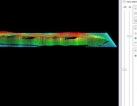

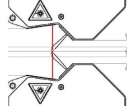

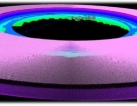

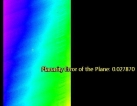

Introducing QuellTech's 3D laser scanner applications for the industrial sector, equipped with advanced laser measurement technology. In today's highly automated production processes, it is crucial to have automated quality assurance systems in place. QuellTech has specialized in 3D measurement using laser scanners based on the triangulation principle.What sets QuellTech's laser measurement technology apart from other methods? Firstly, it enables precise and non-contact 3D measurement of objects with a resolution of up to 1.5 µm. Additionally, it offers high measuring speeds of up to 20 kHz, making it suitable for fast-paced industrial environments. The technology also demonstrates excellent scalability when measuring large objects and showcases high robustness against harsh conditions such as heat, ambient light, and vibrations.Integration into continuous production processes is made easy with QuellTech's laser measurement technology, allowing for seamless inline measurements without interrupting product transports. Moreover, it is tolerant to color and surface texture changes, ensuring accurate measurements regardless of variations in these factors.Looking at specific applications, QuellTech has developed turnkey solutions for industrial image processing in various sectors. For example, in automotive and electronic assemblies, the technology facilitates efficient quality monitoring. In the metal industry, it enables planarity and thickness measurements. Additionally, it can be used for inline monitoring of welding processes, such as weld gap tracking and correction of path.One of QuellTech's notable case studies involves the inspection of seal surfaces. In this scenario, where endless cables are rapidly moving, real-time supervision is essential. The challenges include determining flaws with sizes in the range of hundredths of a millimeter and dealing with surfaces of varying reflectivity and roughness. QuellTech's solution involves the configuration of four Q6 la.

Business

Business