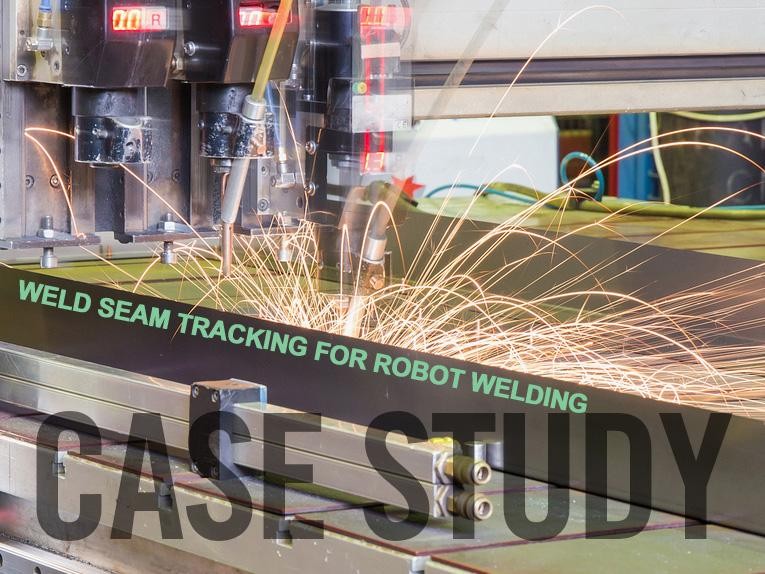

Business Case:Weld Seam Tracking for Robot Welding

Germany, Berlin Land, Berlin - view exact locationProduct Information

Order volume from: On request

Delivery terms: Pickup

Description

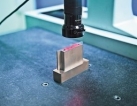

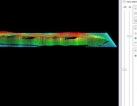

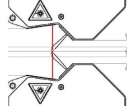

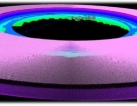

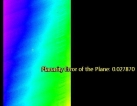

Introducing QuellTech 3D Laser Scanner Applications for IndustryIn today's highly automated production processes, quality assurance needs to be just as automated. QuellTech specializes in 3D measurement with laser scanners based on the triangulation principle, offering numerous advantages compared to other measurement methods.The QuellTech laser measurement technology provides precise and non-contact 3D measurement of objects with a resolution of up to 1.5 µm. It offers high measuring speeds of up to 20 kHz, making it suitable for fast-paced industrial environments. Additionally, the technology is highly scalable, allowing for the measurement of large objects.One of the key advantages of QuellTech laser measurement technology is its robustness against harsh environments such as heat, ambient light, and vibrations. This makes it suitable for use in various industrial settings. The technology can be easily integrated into continuous production processes (inline), allowing for seamless quality control without interrupting the product transports. It also tolerates color and surface texture changes, ensuring accurate measurements regardless of variations.Moreover, QuellTech laser measurement technology enables 3D measurements on glowing parts, making it ideal for industries like automotive, electronic assemblies, and continuous materials. The technology offers turnkey solutions for industrial image processing, allowing for quality monitoring in the metal industry, including planarity and thickness measurements. It also enables inline monitoring of welding processes, such as weld gap tracking and path correction.With a focus on increasing efficiency and quality assurance, QuellTech has developed special solutions in collaboration with its customers. These solutions address specific industry needs, such as the turnkey solutions for industrial image processing in automotive and electronic assemblies. Furthermore, the technology allows for quality monitoring in the metal ind.

Business

Business