zoom Share Printed Circuit Board Assembly in Uninterru

USA, Illinois State, Chicago - view exact locationCategory

- Goods >> Smartphones & Electronics >> Cabling & Wiring Products, Connection Systems >> Signaling & Control Cable

- Goods >> Smartphones & Electronics >> Cabling & Wiring Products, Connection Systems >> Connecting Cable

- Goods >> Smartphones & Electronics >> Cabling & Wiring Products, Connection Systems >> Other Cables, Connections, Connectors, Connectors

Product Information

Order volume from: On request

Delivery terms: Pickup

Description

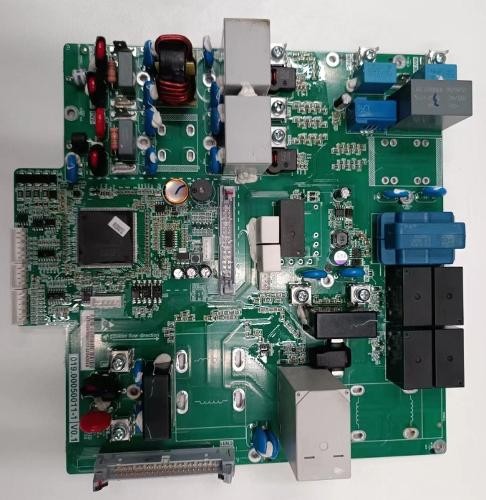

PCB depanelization is a crucial step in the manufacturing process of electronics, specifically in the field of large-scale assembly. This process is particularly essential for enhancing the efficiency of both printed circuit board (PCB) and surface mount (SMT) production lines.

In order to streamline the manufacturing process, PCBs are often designed to consist of numerous smaller individual printed circuit boards, which are later incorporated into the final product. These clusters of PCBs, referred to as panels or multi-blocks, facilitate mass production.

The depanelization of these large panels occurs as a significant process step, depending on the specific product being manufactured. It can take place immediately after the SMT process, after the in-circuit test (ICT), after soldering through-hole components, or even just before the final assembly of the PCBA (Printed Circuit Board Assembly) in its enclosure.

Overall, PCB depanelization plays a crucial role in optimizing productivity and enhancing the overall efficiency of electronic manufacturing, ensuring the seamless integration of PCBs into the final product.

Business

Business