VEN BRUSH

Germany, Berlin Land, Berlin - view exact locationCategory

Product Information

Order volume from: On request

Delivery terms: Pickup

Description

The Venjakob group of companies specializes in providing complete system solutions for surface engineering. They offer a wide range of coating systems for various sectors and materials, including cleaning, pretreatment, varnishing, drying, handling technology, and exhaust air purification. Their goal is to provide the highest levels of quality and customer satisfaction, which is achieved through the expertise of their employees and the use of top-quality purchased parts.

Venjakob employs experienced specialist personnel who develop and implement individual solutions for customers from different sectors, ensuring timely delivery. Their quality work is reflected in comprehensive consultations, backed by tests in their technical center, and completed with assembly and commissioning according to schedule.

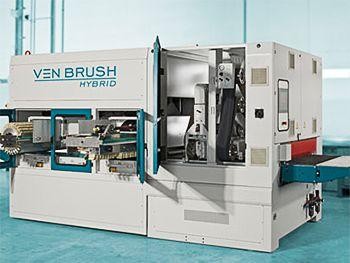

One of their innovative products is the VEN BRUSH system technology, designed by Venjakob Maschinenbau GmbH & Co KG. This system is based on high pressure at low speed and includes special hold-down brushes for processing profiled workpieces. The motor-driven height adjustment and infinite rotational speed setting provide maximum perfection and flexibility for workpieces of varying shapes and sizes.

The VEN BRUSH system features a high-performance vacuum transport belt that ensures reliable transport of both small and large format workpieces. It also includes a built-in Molton roller for constant cleaning of the conveyor belt. The system offers a wide performance spectrum and can be customized with 2 to 5 unit positions, allowing for future expansion to meet changing production requirements.

The VEN BRUSH system is capable of operating at various widths and lengths, depending on production requirements. It offers short change times and high operating comfort, thanks to the quick-exchange brush system with a push-in system and coupling. The system also includes an optional infinite angle setting for impeccable edge processing.

For special surface processing, the VEN BRUSH system offers the use of a structured brush unit. This brush is ideal for structurizing furniture parts, hardwood and softwood, and flooring boards, or achieving an antique look. Additionally, the system can be extended with a dust removal system and ionization system to ensure optimum workpiece cleanliness.

Whether as a standalone station or integrated into an existing machine line, the VEN BRUSH system provides an individual solution that can be easily operated using a control panel or touch panel. The system's high-performance technology and control system configuration take into account all interfaces, including higher-ranking control and monitoring.

Business

Business