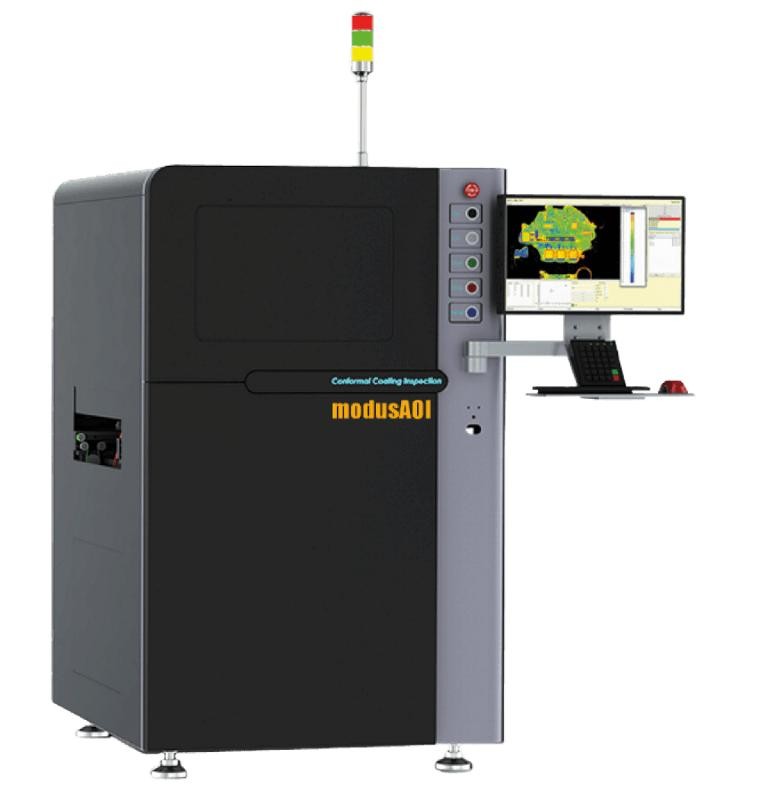

modusAOI MLD V2.0-S3-IDL/IOL/IUL

Germany, Berlin Land, Berlin - view exact locationProduct Information

Order volume from: On request

Delivery terms: Pickup

Description

The triple AOI system is an advanced tool designed specifically for the electronics manufacturing industry. It excels in providing simultaneous inspection capabilities at multiple stages of the production process. Whether it's inspecting components before or after being exposed to the wave soldering oven, or conducting inspections from the top and bottom, this system ensures thorough quality control.

Featuring three scanner units equipped with multi-LED illumination, the system utilizes patented special optics to produce clear and parallax-free images. To facilitate efficient operation, it includes three modus control units for easy navigation and control.

In terms of specifications, the transport module of the system measures 1200mm (47.2 in.) in length. This ensures compatibility with a wide range of production setups.

The triple AOI system offers several noteworthy features. For instance, it enables the simultaneous inspection of both the upper and lower sides of the PCB before and after the soldering process. Additionally, it provides the option for automatic cleaning of the lower inspection area using an air knife, ensuring optimal cleanliness.

Furthermore, the system is capable of handling various inspection tasks, including SMD placement, THT solder joints, conformal coating, and full screening for solder beads. Its versatility extends to the ability to capture multiple barcodes and data-matrix codes on the multi PCB, streamlining the tracking and record-keeping processes.

Lastly, the system's impressive scan range of 420 x 530 mm guarantees comprehensive coverage and accuracy during inspections.

Business

Business