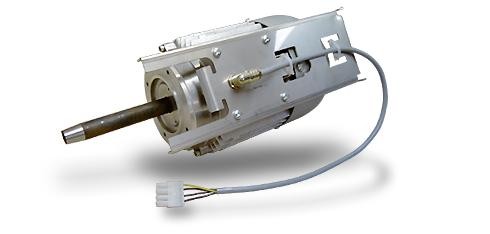

Permanent Excited Reluctance Motors

Germany, Berlin Land, Berlin - view exact locationProduct Information

Order volume from: On request

Delivery terms: Pickup

Description

Electric motors for high-speed applications, typically ranging from approximately 6,000 to 30,000 min-1, require meticulous design considerations for optimal performance. These motors are specifically engineered to excel in industries where speed is a crucial factor. The key areas of focus during the design process include bearings, greasing, and ventilation.

The selection and implementation of high-quality bearings are of paramount importance in these motors. Careful attention is given to choosing bearings that can withstand the intense rotational speeds, ensuring smooth and reliable operation. Additionally, the motor design incorporates advanced greasing techniques to minimize friction and reduce wear on the bearings. This optimizes the efficiency and longevity of the motor, resulting in enhanced performance and reduced maintenance requirements.

Furthermore, effective ventilation is critical to prevent overheating and ensure proper cooling of the motor components. The design includes strategically positioned ventilation channels or fans that facilitate the dissipation of excess heat generated during high-speed operation. This not only improves the overall efficiency of the motor but also safeguards against potential damage caused by excessive temperatures.

In summary, the electric motors tailored for high-speed applications are engineered with meticulous attention to crucial aspects such as bearings, greasing, and ventilation. By incorporating specialized design features, these motors deliver superior performance, reliability, and longevity in industries where speed plays a vital role.

Business

Business