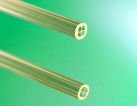

Стеклянные капилляры

Германия, Берлин земля, Берлин - посмотреть точное местоположениеКатегория

- Товары >> Медицинские товары >> Медицинское оборудование и материалы >> Диагностическое медицинское оборудование

- Товары >> Медицинские товары >> Медицинское оборудование и материалы >> Лабораторное медицинское оборудование

- Товары >> Медицинские товары >> Медицинское оборудование и материалы >> Стоматологическое и зуботехническое оборудование

Информация о товаре

Объем заказа от: По запросу

Условия доставки: Самовывоз

Бизнеса

Бизнеса