2D-/3D-Software für maschinelle Bildverarbeitung

Deutschland, Berlin Land, Berlin - siehe genauen StandortKategorie

Produktinformation

Auftragsvolumen ab: Auf Anfrage

Lieferbedingungen: Aufsammeln

Auftragsvolumen ab: Auf Anfrage

Lieferbedingungen: Aufsammeln

Barrenmessungen auf Aluminium oder Stahl vor dem Scalping

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Barrenmessungen auf Aluminium oder Stahl vor dem Scalping

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Lasersensor Q4 für 2D/3D-Anwendungen

0 USD

Deutschland,

Berlin Land, Berlin

Lasersensor Q4 für 2D/3D-Anwendungen

0 USD

Deutschland,

Berlin Land, Berlin

Schichtdickenmessung in der Materialprüfung

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Schichtdickenmessung in der Materialprüfung

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

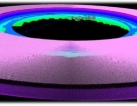

Qualitätsprüfung von Schleifscheiben durch 3D-Messung

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Qualitätsprüfung von Schleifscheiben durch 3D-Messung

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Lasersensor zur Inspektion von Dichtungsoberflächen

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Lasersensor zur Inspektion von Dichtungsoberflächen

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Messung von Aluminium-/Stahlbarren vor dem Scalping

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Messung von Aluminium-/Stahlbarren vor dem Scalping

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

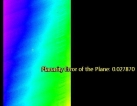

Erkennung von Oberflächenfehlern mittels Lasertriangulation

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Erkennung von Oberflächenfehlern mittels Lasertriangulation

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Geschäftsfall: Schweißnahtverfolgung beim Roboterschweißen

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin

Geschäftsfall: Schweißnahtverfolgung beim Roboterschweißen

Preis auf Anfrage

Deutschland,

Berlin Land, Berlin